Process of Manufacturing Hotel Safes

Welcome to our article on the process of manufacturing hotel safes. In this article, we will look in-depth into what hotel safes are, why they are important for guests, where they are usually installed in hotel rooms, and the manufacturing process involved in creating these essential security devices.

What are Hotel Safes?

How are Hotel Safes Different from Regular Safes?

Hotel safes, also known as hotel room safes, hotel safe boxes, or hotel safety boxes, are secure storage devices specifically designed for use in hotel rooms. They differ from regular safes in size, functionality, and convenience. Hotel safes are typically smaller and more compact than traditional safes, allowing them to be easily installed in hotel rooms without taking up too much space.

Why are Hotel Safes Important for Guests?

Hotel safes offer a secure place for guests to store their valuable belongings, such as cash, jewellery, passports, and important documents. Knowing that their valuables are protected during their stay provides them peace of mind. Hotel safes are crucial in establishing trust and ensuring a positive guest experience.

Where are Hotel Safes Usually Installed in Rooms?

Hotel safes are typically installed in a concealed location within the hotel room. Common installation spots include inside the wardrobe, behind a painting, or within a dedicated safe cabinet. These locations are chosen to provide easy access for guests while maintaining the security and confidentiality of their stored items.

Designing Hotel Safes

What are the Key Factors to Consider When Designing Hotel Safes?

When designing hotel safes, several key factors need to be considered. First and foremost, the safe should be tamper-proof and resistant to forced entry. It should also be user-friendly, allowing guests to operate and access their belongings easily. The design must enhance the hotel room’s overall visual appeal and ensure a smooth and cohesive integration.

How is the Size and Weight of Hotel Safes Determined?

The size and weight of hotel safes are determined based on various factors. One of the primary considerations is the available space within the hotel room. The safe should be compact enough to fit into the designated installation area without causing any inconvenience to guests. Additionally, the weight of the safe is carefully calculated to ensure stability and prevent toppling.

What Types of Locks Are Commonly Used in Hotel Safes?

A variety of locking mechanisms can be found in hotel safes. The most common types include electronic keypad, keycard, and combination locks. Electronic keypad locks provide guests with a convenient, keyless entry system, while keycard locks offer compatibility with the hotel’s existing keycard system. Combination locks, on the other hand, require a code to be inputted to access the contents of the safe.

The Manufacturing Process

What Materials are Used to Manufacture Hotel Safes?

Hotel safes are manufactured using robust materials that ensure strength and security. High-quality steel is often used to construct a safe body, making it highly resistant to tampering and break-ins. The interior lining of the safe may be lined with soft materials such as felt or velvet to protect delicate items.

What is the Process of Manufacturing a hotel safe box?

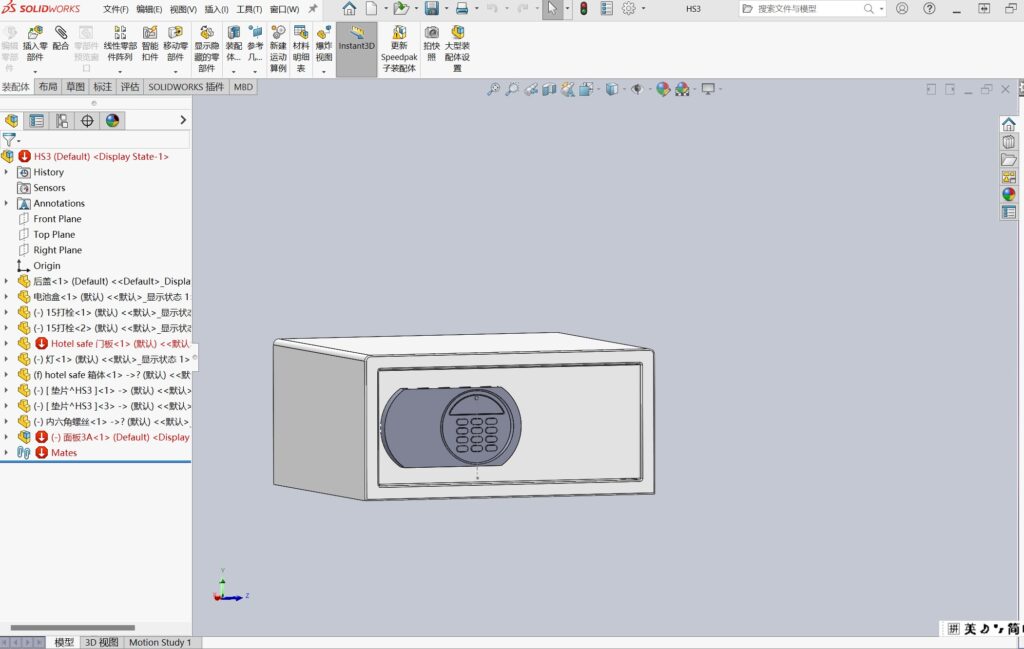

The manufacturing process of hotel safes involves several stages. It starts with design and material selection, where engineers work closely to create an aesthetically pleasing and secure product. After finalizing the design, the fabrication process begins. This includes cutting, bending, and shaping the steel to form the safe body and door. After that, the various components are assembled, including the locking mechanism and hinges. Finally,The safe undergoes thorough testing and quality assurance procedures to guarantee its compliance with the most stringent industry benchmarks.

How Long Does it Take to Manufacture a Hotel Safe?

The time required to manufacture a hotel safe depends on various factors, such as the complexity of the design, the production capacity of the manufacturer, and the demand for the product. On average, it can take about 10-30 days to complete the entire manufacturing process.

Quality Control Measures

How are Hotel Safes Tested for Reliability and Durability?

Hotel safes undergo rigorous testing procedures to ensure their reliability and durability. This includes testing the locking mechanism under various conditions, simulating different types of break-in attempts, and evaluating the overall structural integrity of the safe. Additionally, safes are tested for resistance to fire, water, and other environmental factors to ensure they can withstand adverse conditions.

What Safety Standards Should Hotel Safes Comply With?

Hotel safes should comply with industry standards and certifications, such as UL (Underwriters Laboratories) certification and EN (European Norm) standards. These safety standards set the benchmark for the quality and performance of hotel safes and ensure they meet the necessary security requirements.

What Happens if a Hotel Safe Fails Quality Control Checks?

If a hotel safe fails quality control checks, it is either repaired or discarded, depending on the severity of the issue. Manufacturers prioritize safety and the satisfaction of their customers, so any safes that do not meet the required standards are either fixed or replaced to maintain the highest level of quality.

Technicians and Maintenance

What Roles Do Technicians Play in the Manufacturing Process?

Technicians play a vital role in the manufacturing process of hotel safes. They are responsible for assembling the various components, installing the locking mechanisms, and conducting post-production tests to ensure that the safes function correctly. Their expertise and attention to detail are crucial in producing high-quality and reliable hotel safes.

How Often Should Hotel Safes Be Inspected and Serviced?

Hotel safes should be regularly inspected and serviced to ensure their continued functionality and security. The regularity of inspections can differ based on variables like utilization, environmental conditions, and guidance provided by the manufacturer. However, a general rule of thumb is to have the safes inspected and serviced at least once a year.

What are the Common Maintenance Issues with Hotel Safes?

Common maintenance issues with hotel safes can include electronic malfunctions, battery replacements, lock resets, and general wear and tear. Regular maintenance can quickly spot and resolve these problems, ensuring that the safes remain operational and provide a secure storage solution for hotel guests.